OFFSHORE

The offshore Oil & Gas market is important and will be the sector to focus on for growth. Higher specifications and exploration activity in deeper waters for oil and gas will be strong drivers going forward. Our offshore solutions are designed to optimise efficiency and minimise your operating risks.

OFFSHORE EQUIPMENT

- Svanehøj Pumps Singapore Pte. Ltd

- Wärtsilä Water System, UK

- Svanehøj Danmark A/S, Denmark

- Flender, Germany

- Gardner Denver, UK

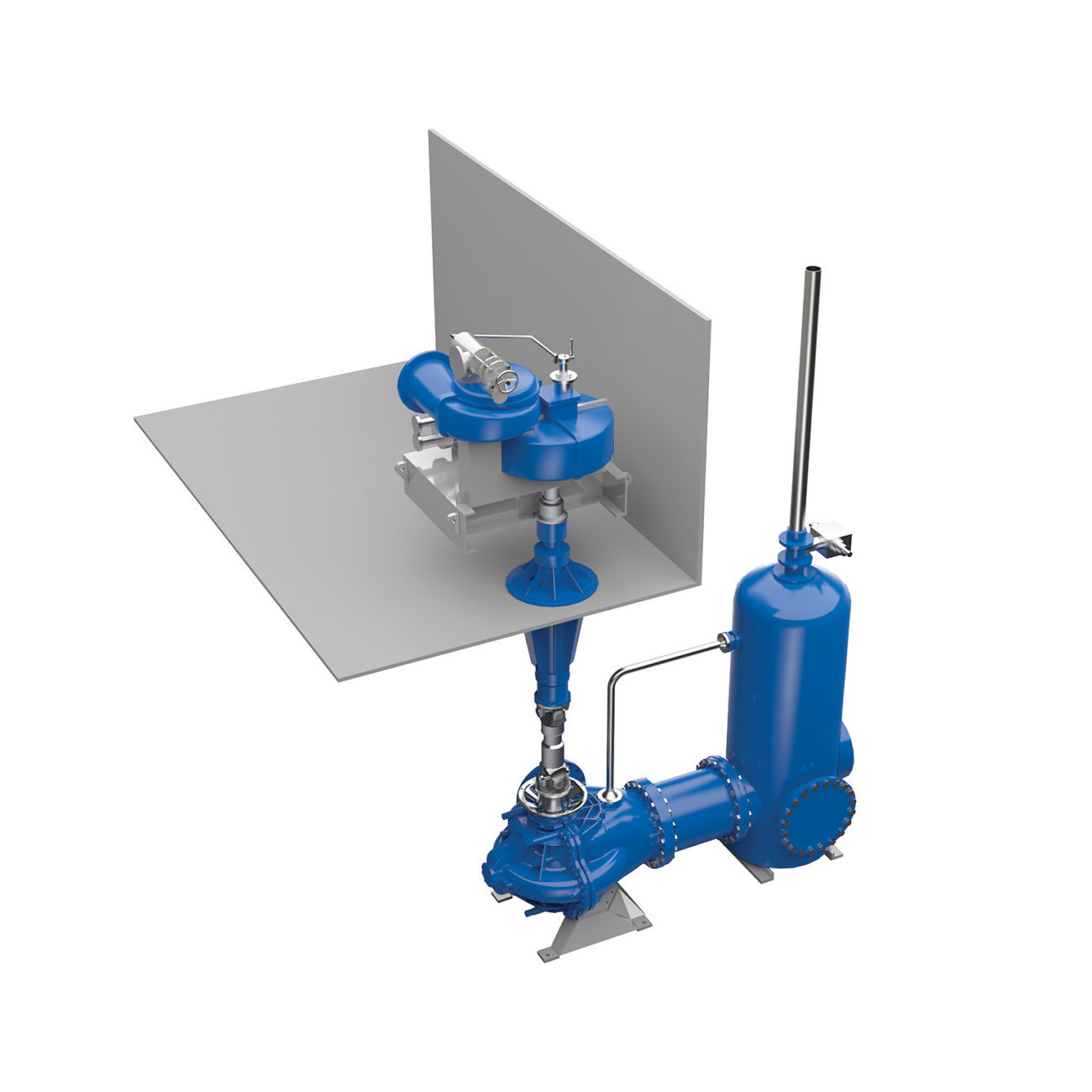

CG Pump Vertical in-line single stage pump in single suction impeller, radially split casing with flexible spacer coupling and hydrodynamic sleeve bearing. |  C2G Pump Vertical in-line overhung pumps with single suction impeller, radially split casing with rigid coupling options. Comes with ball bearings and mechanical seal as an integral unit which enables a very quick maintenance turnaround time. |

CGX (CGL,CGM,CGH) Pump The CGX pump is a single-suction inline centrifugal pump, designed for a reliable and efficient operation. It comes with three pressure classes which are CGL, CGM & CGH and a large number of pump sizes. |  CA Pump Between bearings pumps which can operate in both vertical inline foot mounted and horizontal installations. Available in both single and two stage impeller. Compact axially split casing design with double suction capabilities with low NPSH requirement. |

CB Pump Between bearings single stage double suction impeller pumps that can operate in both vertical and horizontal installations. Low shaft stiffness ratio and compact design in multiple orientations. |  Cargo Oil & Ballast Pumping Systems Characterised by a separate pump room in front of the engine room, Cargo oil and ballast pumping system offers easy access for inspection and maintenance as well as great flexibility in choice of prime mover. |

Dolphin Pump Vertical in-line, single-stage, single/double suction, overhung pumps with rigid coupling, radially split. Option for external bearings/flexible coupling on vertical single suction pumps. Horizontal end suction, single stage, single suction, overhung pumps close-coupled or base-plated with flexible coupling. |

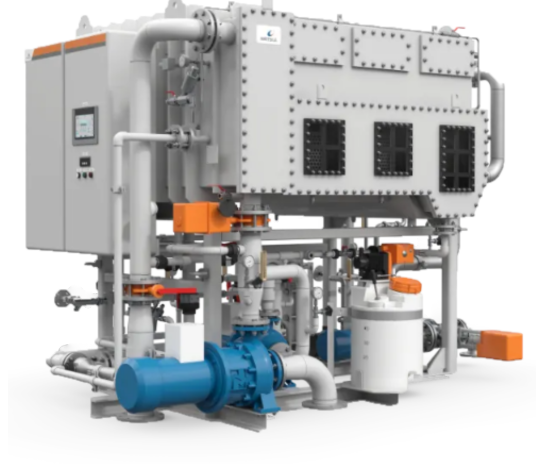

Sewage Treatment Plants Sewage treatment plants (STPs) from Wärtsilä are the most cost-effective and safe answer for every ship or offshore platform to dispose of wastewater at sea. |  Vacuum Collection System The vacuum collection systems from Wärtsilä Water & Waste use differential air pressure to transport sewage from the toilet bowls, and other sanitary fittings, to the Sewage Treatment Plant (STP) or independent collection tank. |

Vacuum Toilet System Wärtsilä vacuum toilets have been designed to be mechanically simple, operationally reliable, and stylish in appearance. By using only approximately 1 liter of water per flush, the amount of wastewater is dramatically reduced. |  Single Stage Desalination Plants Wärtsilä’s Single Stage Desalination (SSD) plant generates high quality freshwater in an energy efficient way. With a capacity from 8 to 35 tons/day, it is ideal for converting seawater for use as drinking or technical water onboard ships or offshore installations. |

Horizontal inner Tube Evaporator (HiTE) The Wärtsilä Horizontal inner Tube Evaporator (HiTE) is a multi-effect evaporator specifically designed for producing small to medium capacities of 30 to 175 tons of distillate per day. The HiTE operates smoothly even at partial load. |  Multi-Stage Flash (MSF) Evaporator Wärtsilä's Multi-Stage Flash (MSF) evaporator is used for producing distillate (fresh water) from sea, well or industrial water. The MSF is able to produce up to 1500 tons of distillate per day. |

Oily Water Separators With the aid of Wärtsilä's Advanced Oily Water Separators all environmental aspects regarding bilge water issues are easily handled. They give the operator effective control over all bilge media as well as over any discharges made into the sea. |  Ballast Water Management Systems Wärtsilä Water & Waste takes pride in developing two advanced lines of Aquarius Ballast Water Management Systems (BWMS) that enable vessels of all types to meet the performance discharge obligations. BWMS offerings, one based on filtration & UV and the other on filter & side stream electro-chlorination (EC). |

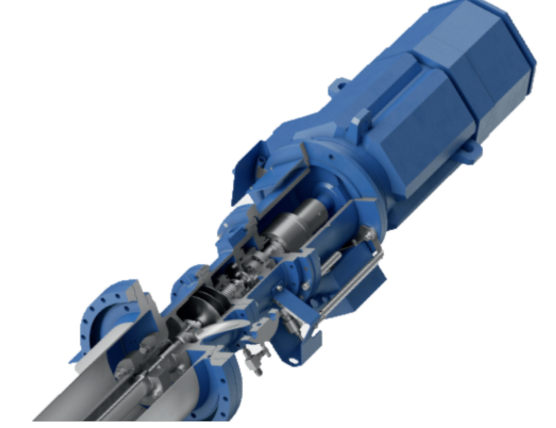

DEEPWELL GAS CARGO PUMPS Reliably, safely and energy efficiently which makes Svanehøj DW Cargo pumps the ideal choice for the conversion to future fuels, ensuring safe and reliable processes for Cargo Bunkering Vessels and Carriers of all sizes and tank types. |

Deep Well Fuel Marine Pump The renowned Svanehøj deepwell fuel pump provides a solution that not alone supports eco-friendly LNG-fuelled vessels but also alternatives such as LPG, ethane, methanol, and even ammonia. |

Deepwell offshore cargo pumps Svanehøjs offshore process and cargo (OPC) pumps have been specifically developed to meet the growing demands, high standards and comprehensive specifications for offshore operations. |

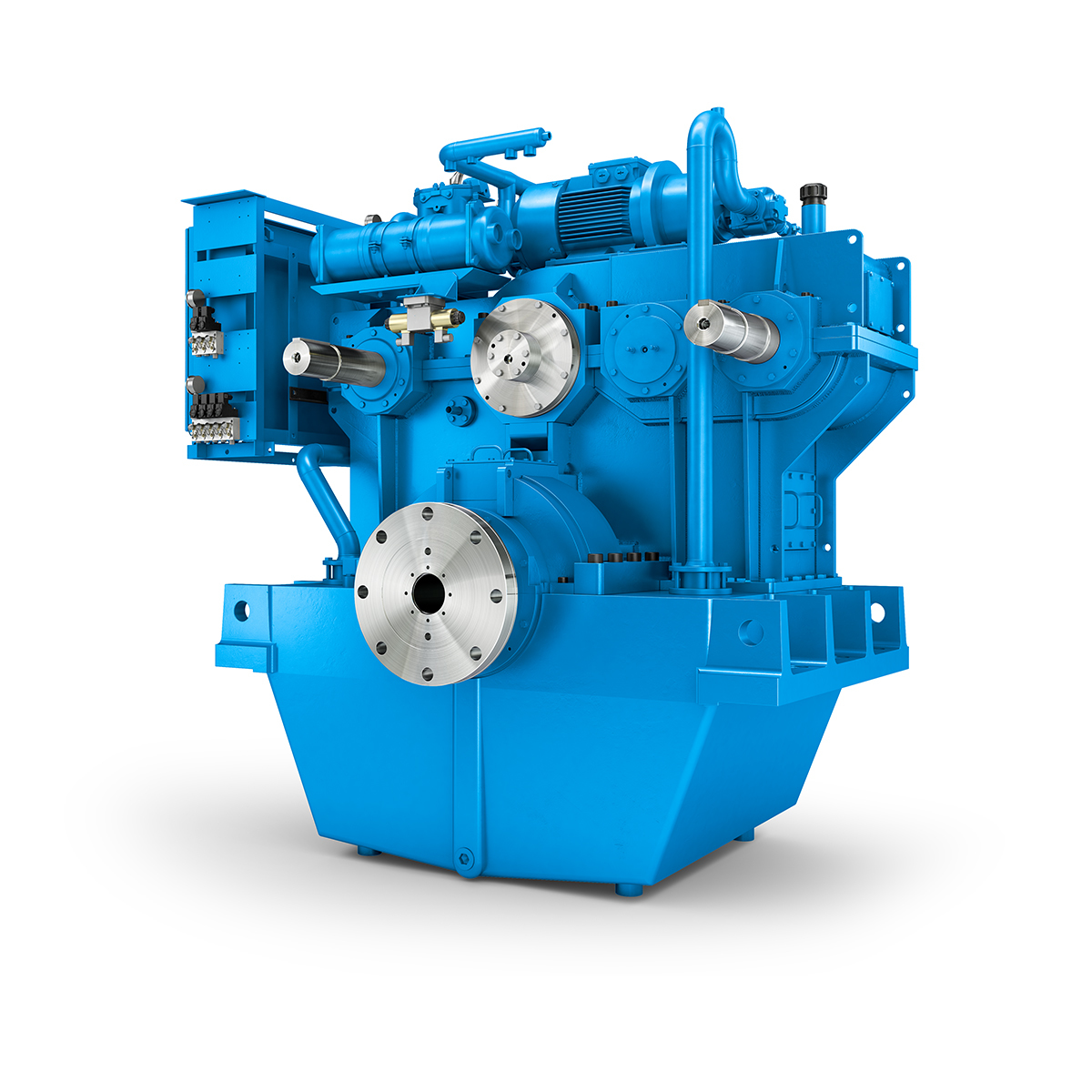

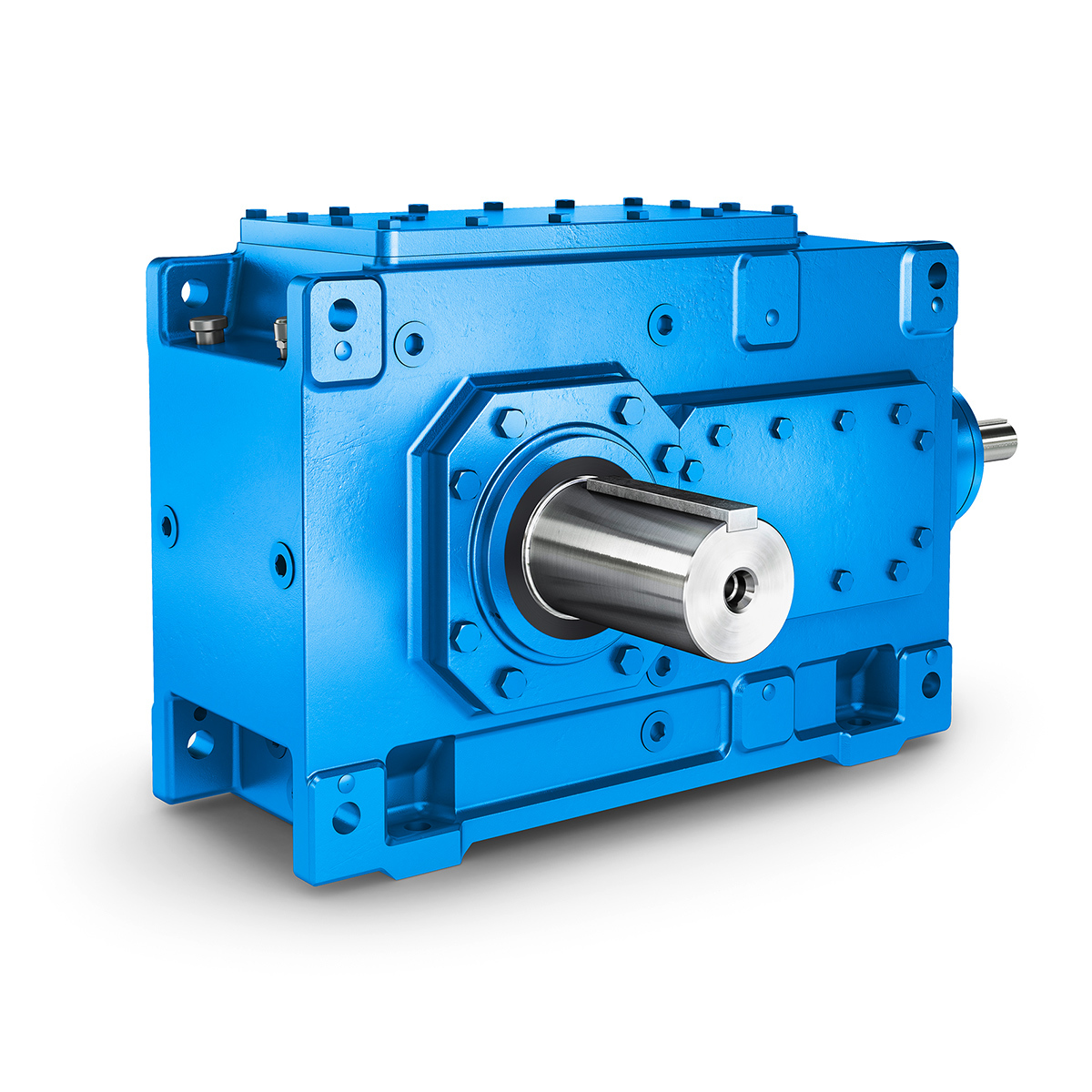

NAVILUS Single input / output marine gearboxes Single input/single output marine gearboxes are used in river boats and coastal vessels, but also in ocean-going vessels. |  HELICAL GEAR UNITS AND BEVEL-HELICAL GEAR UNITS The FLENDER® helical and bevel-helical gear unit portfolio is by far the most comprehensive range of industrial gear units in the world. |

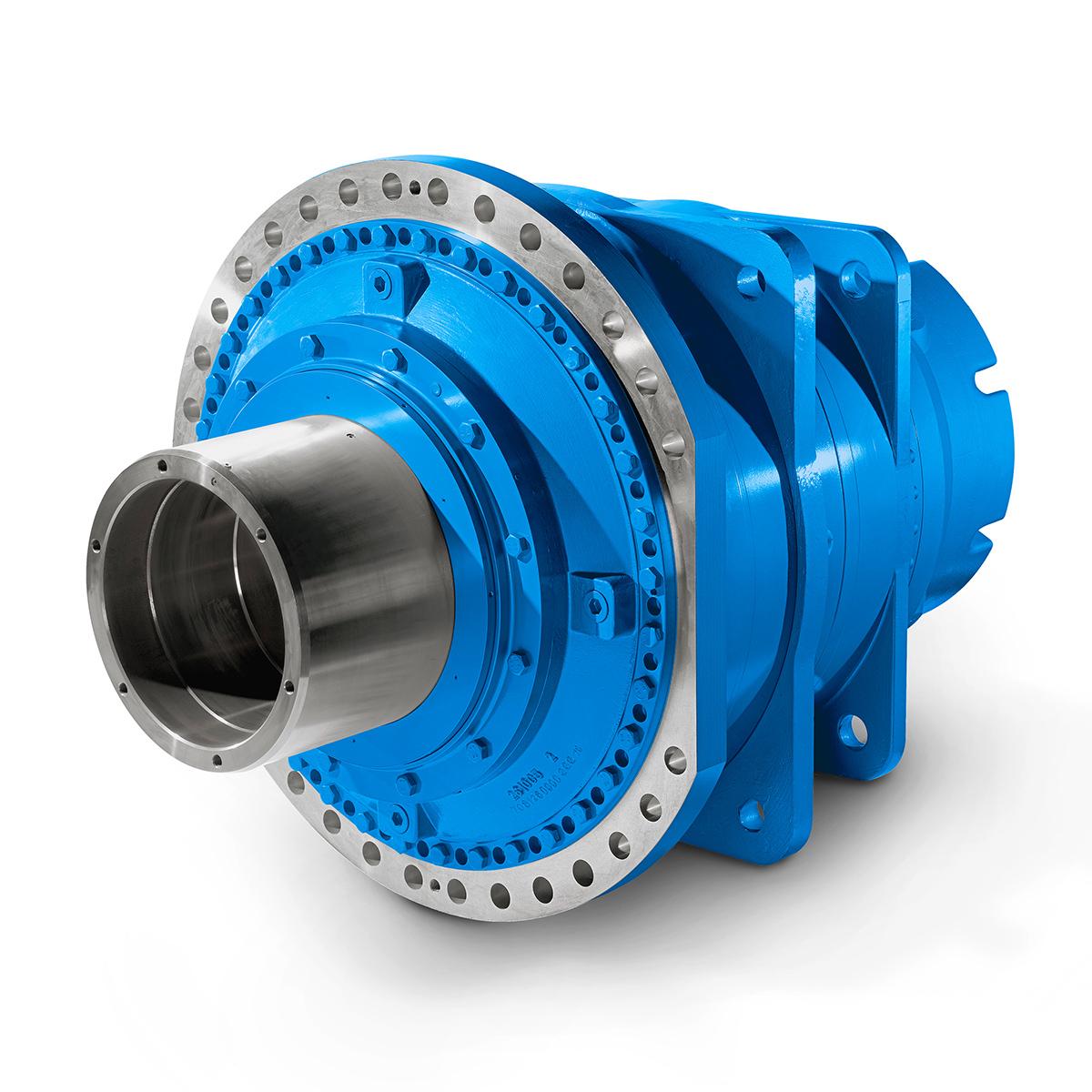

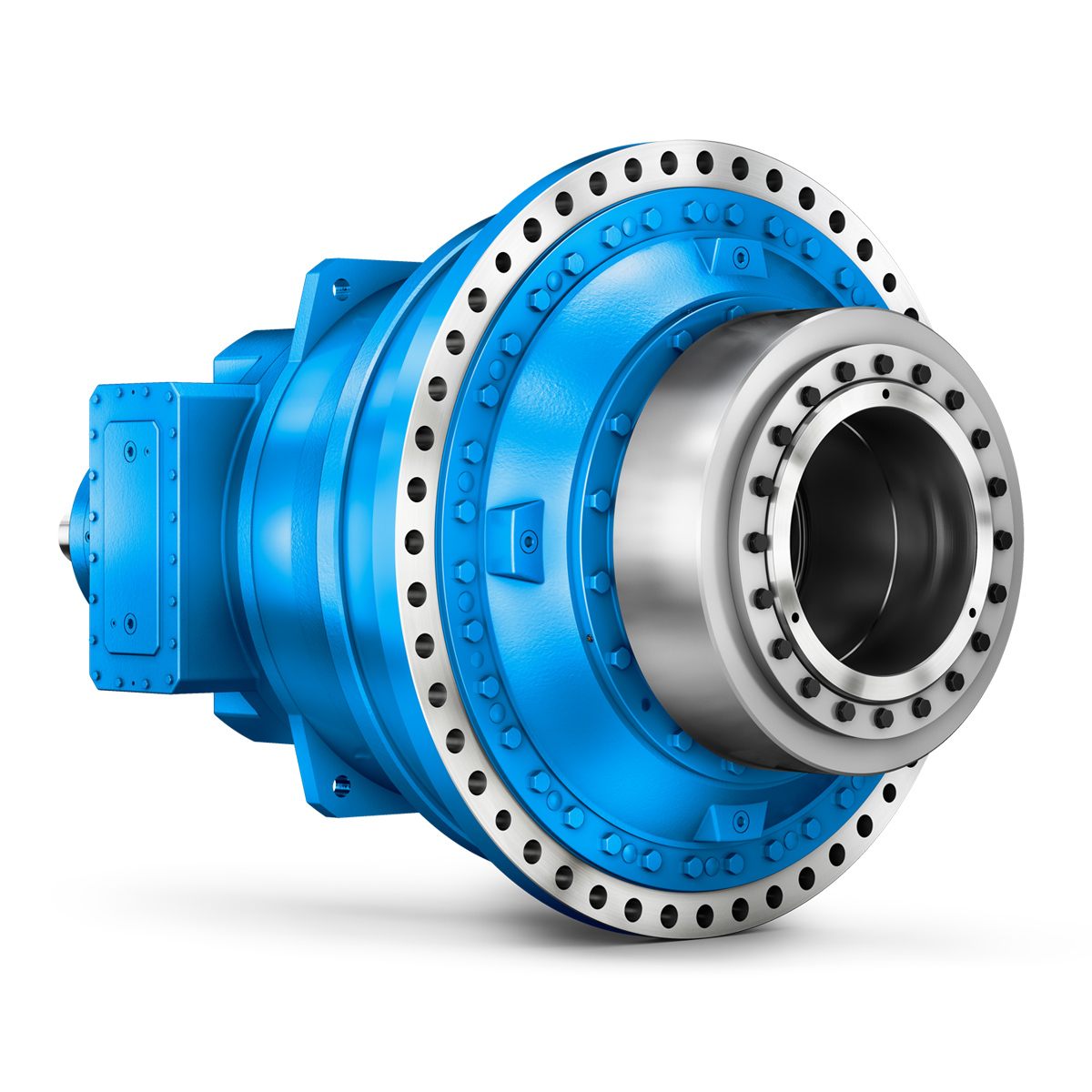

PLANUREX 2 GEAR UNITS The PLANUREX gear units’ robust design guarantees process stability above all. The resulting reduction in complexity makes it possible to produce economic batch sizes to a high quality standard. |  PLANUREX 3 GEAR UNITS PLANUREX 3 offers a complete, fully standardized planetary gear unit portfolio, combined with short delivery times worldwide, an excellent price/performance ratio and very high modularity. |

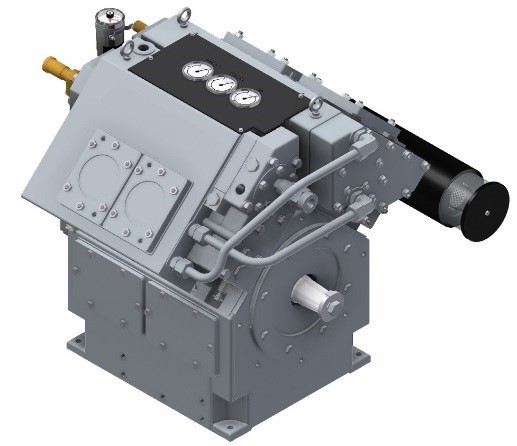

FLENDER oil supply systems FLENDER oil supply systems are used for cooling and/or lubricating gear units. Flender uses products which have been specially selected from the market supply, and are made and tested in accordance with Flender specifications. |

Reavell 5417N The H 5417 is a 4 stage, water cooled, lubricated compressor offering reduced wear, excellent reliability, longer life, simple maintenance and extended service intervals. |  Reavell 5437N The H 5437 is a heavy duty 4 stage, water cooled, lubricated compressor set designed to operate in the harshest of environments but easy to maintain. |

5200 RANGE TWO STAGE AIR COMPRESSOR Reavell’s two-stage, splash or pressure lubricated compressors. Available in a range of models featuring either direct or “V” drive, and the option of air or water cooling built in. the 5200 series features a compact, plug-and-play design that works to help operators maximize performance and efficiency. |  MAKO AirCharge AirCharge machines are compact and fully integrated compressors. They are designed for the 5000 psi user where quality, convenience and low noise are paramount and space is tight. The AirCharge is highly reliable, and offers a long service life for a cost-effective operation. |